Products Center

GHL series high speed mixer granulator

High Effect Damp Mixer Granulator is suitable for pharmaceutical industry, foodstuff industry, chemical industry and so on. It features reasonable structure high speed. Professional Pharmacy Equipment Supplier welcome inquiry!

Product Details

Application

1. It is suittable for pharmaceutical industry, foodstuff industry, chemical industry and so on. The granule is made from powder to damp granule in which the adhesive should be injected in it.

Features

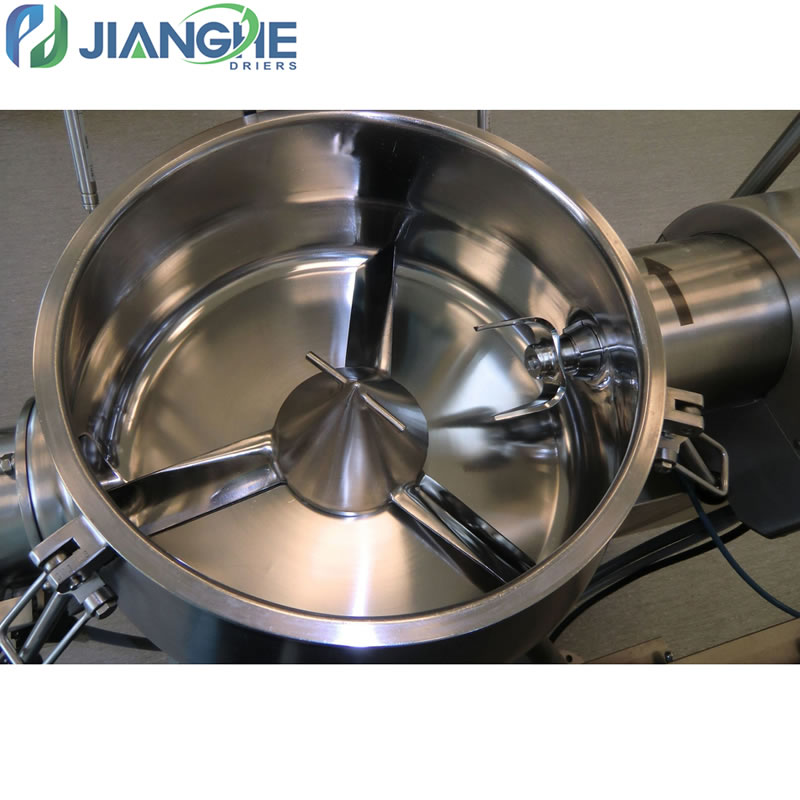

2.The machine adopts horizontal cylinder structure, its structure is reasonable, no deed corner.

3.Air filled seal shaft for to drive. When washing , it can be changed to water.

4. Fluidized granulation, the granule is around ball shape. Its fluid is good.

5. The dry mixing time is 2 minutes and the granulating time is 1-4 minutes. Compared to the traditional process, 4-5 times of efficiency is raised.

6.Dry mixing ,humid mixing and granulating are finished in the same sealed container. It is in conformity with the requirements of GMP.

7. The whole operat ion has strict safe and protect ivemeasures.

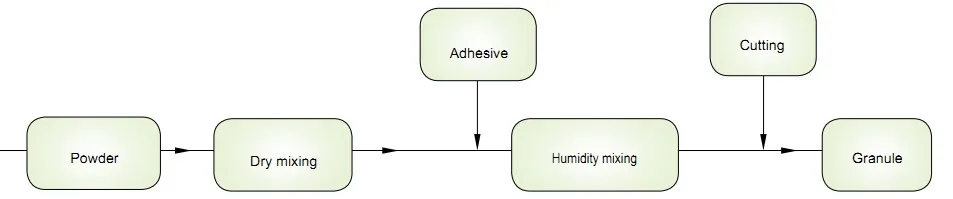

Principle

8.The powder raw material and adhesive in a cylinder are fully mixed to a humid soft material by mixed oar at the bottom. .Then it is cut by high-speed cutter and become uniform damp granules.

Technical Parameters

TECHNICAL PARAMETERS(STANDARD TYPE)

| item | Model | ||||||||

| Name | unit | 10 | 50 | 150 | 200 | 250 | 300 | 400 | 600 |

| Capacity | L | 10 | 50 | 150 | 200 | 250 | 300 | 400 | 600 |

| Output /batch | kg/batch | 3 | 15 | 50 | 80 | 100 | 130 | 200 | 280 |

| Mixing speed | r.p.m. | 300/600 | 200/400 | 180/270 | 180/270 | 180/270 | 140/220 | 106/155 | 80/120 |

| Admix power | kw | 1.5/2.2 | 4/5.5 | 6.5/8 | 9/11 | 9/11 | 13/16 | 18.5/22 | 22/30 |

| Cuting speed | r.p.m. | 1500/3000 | 1500/3000 | 1500/3000 | 1500/3000 | 1500/3000 | 1500/3000 | 1500/3000 | 1500/3000 |

| Cuting power | kw | 0.85/1.1 | 1.3/1.8 | 2.4/3 | 4.5/5.5 | 4.5/5.5 | 4.5/5.5 | 6.5/8 | 9/11 |

| Compressed air consumption | 3 | 0.6 | 0.6 | 0.9 | 0.9 | 0.9 | 1.1 | 1.5 | 1.8 |

| m /min | |||||||||

| Weight | kg | 250 | 500 | 800 | 1000 | 1300 | 1800 | 2200 |

2600 |

Drawing of Flow Plan Overall Dimensions

TECHNICAL PARAMETERS

| Model | A | B | CxD | E | F |

| 10 | 270 | 750 | 1000x650 | 745 | 1350 |

| 50 | 320 | 950 | 1250x800 | 970 | 1650 |

| 150 | 420 | 1000 | 1350x800 | 1050 | 1750 |

| 200 | 520 | 1100 | 1650x850 | 1450 | 2050 |

| 250 | 550 | 1100 | 1650x850 | 1450 | 2050 |

| 300 | 550 | 1150 | 1700x900 | 1500 | 2200 |

| 400 | 670 | 1150 | 1860x1050 | 1650 | 2350 |

| 600 | 750 | 1250 | 2000x1050 | 1800 | 2400 |

Wechat

Wechat