Products Center

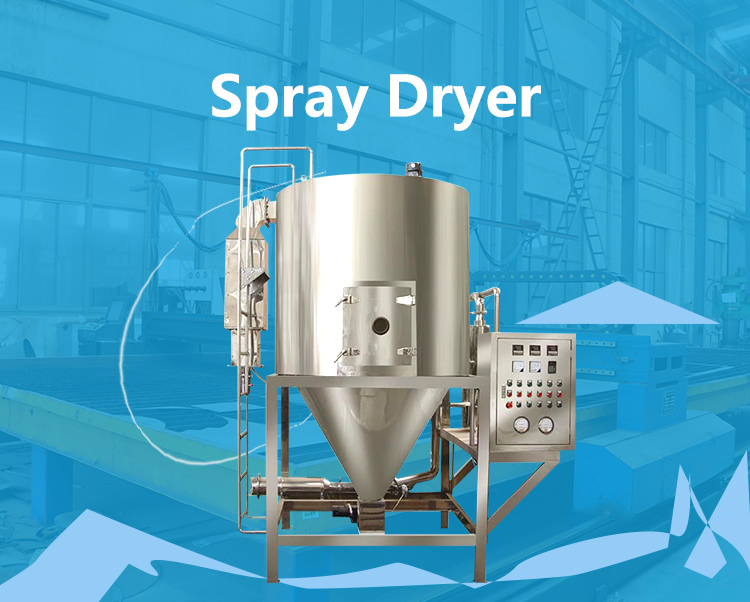

LPG Series High Speed Centrifugal Spray Dryer

LPG series high-speed centrifugal atomizing drier is a special equipment and is suitable for drying emulsion, suspending liquid, liquor and so on. Particularly, it has worked perfect to dry polymers and resins; dyestuff and pigment; ceramics, glass, derust agent; pesticide; carbohydrate, dairy products; detergent and surfactant; fertilizer, organic compound, inorganic compound and so on.

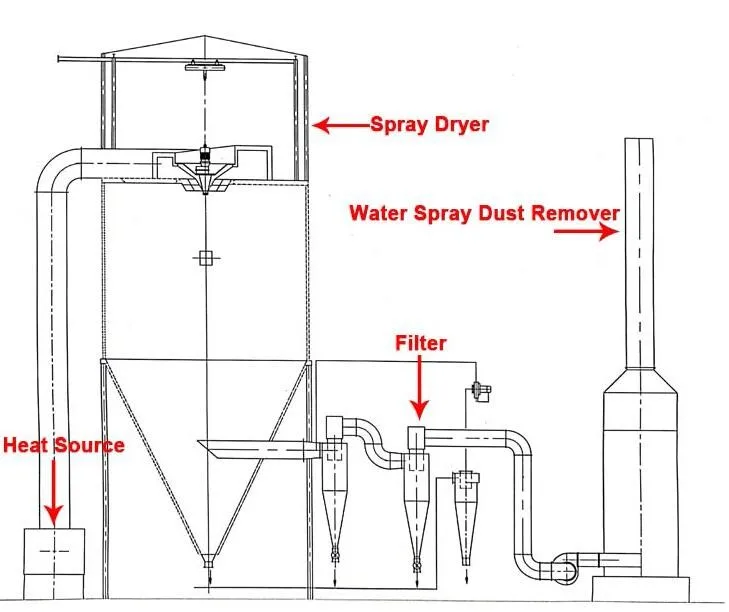

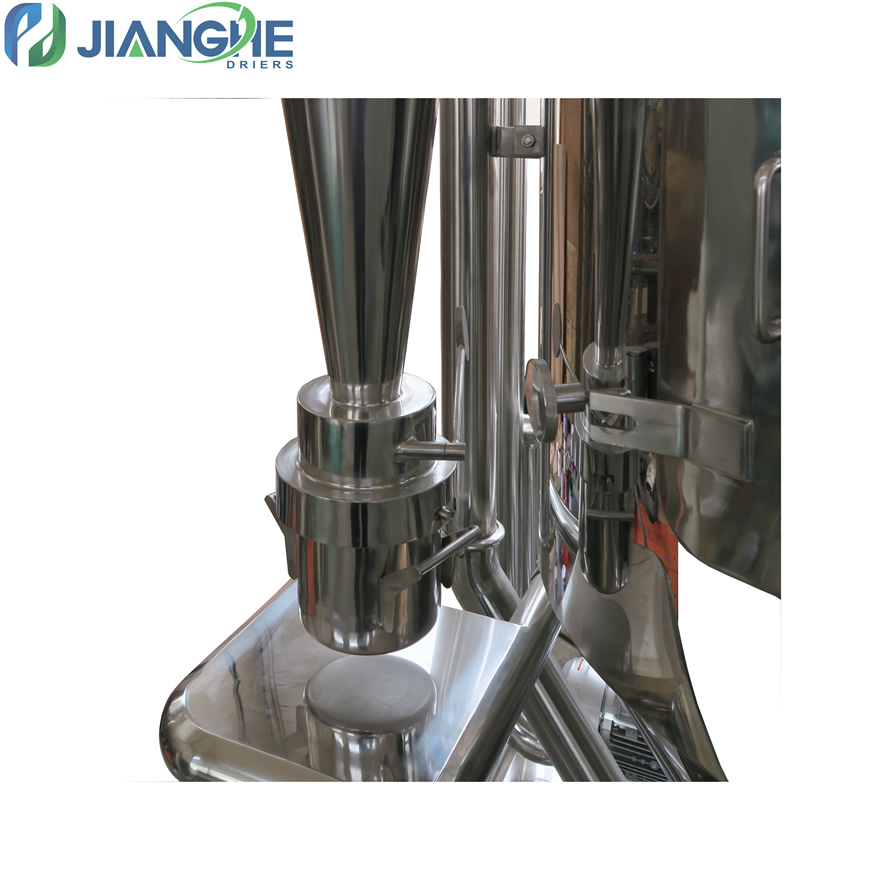

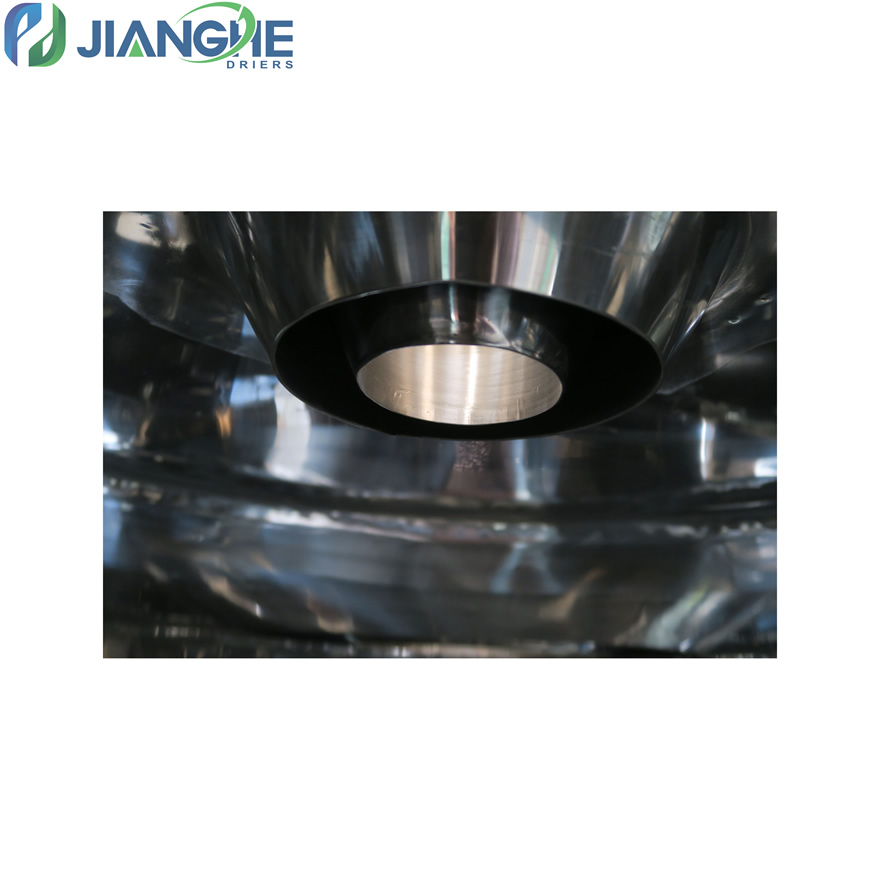

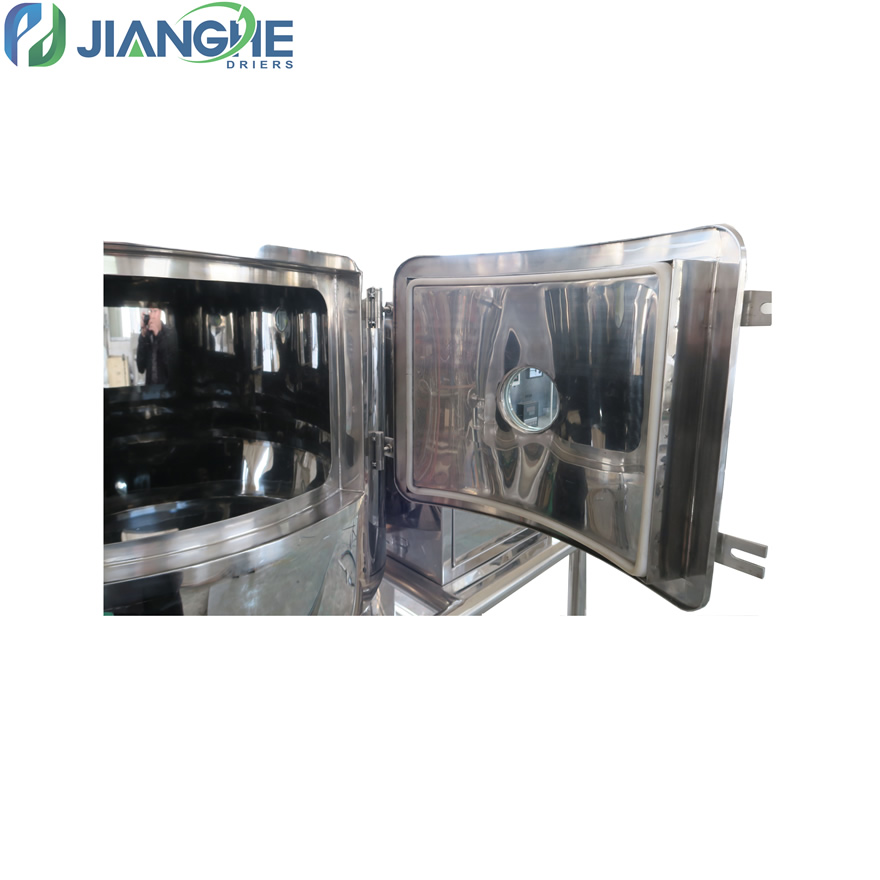

After filtering and heating the air enters into the air distributor at the top of the drier. The hot air enters into the drying chamber in the spiral spray at the top of the tower. The material liquid will rotate and be sprayed into liquid beads. Through the very short time of contacting the heat air, the materials can be dried into the finished products. The finished products will continuously output through the bottom of dryer and separator. The waste gas will be discharged from blower.

| Dimension / Model | 5 | 25 | 50 | 150 | 200-2000 |

| Inlet Temperature °C | 140-350 automatic control | ||||

| Outlet Temperature °C | 80-90 | ||||

| Max. Evaporation Capacity (kg/h) | 5 | 25 | 50 | 150 | 200-2000 |

| Atomizing Method | compressed air drive | mechanical drive | |||

| Revolution (r.p.m) | 25000 | 18000 | 18000 | 15000 | 8000-15000 |

|

Revolution (r.p.m) Diameter of Atomizing Disc (mm) |

50 | 120 | 120 | 150 | 180-240 |

| Heat Source | electricity | steam+electricity | steam+electricity, oil, oil fuel, hot air furnace | ||

| Max. Heating Power (kw) | 9 | 36 | 72 | 99 | |

| Overall Dimensions(L×W×H)(m) | 1.8×0.93×2.2 | 3×2.7×4.26 | 3.5×3.5×4.8 | 5.5×4×7 | depends on actual situation |

| Dried Powder Restoring Rate (%) | ≥95 | ||||

Wechat

Wechat