Products Center

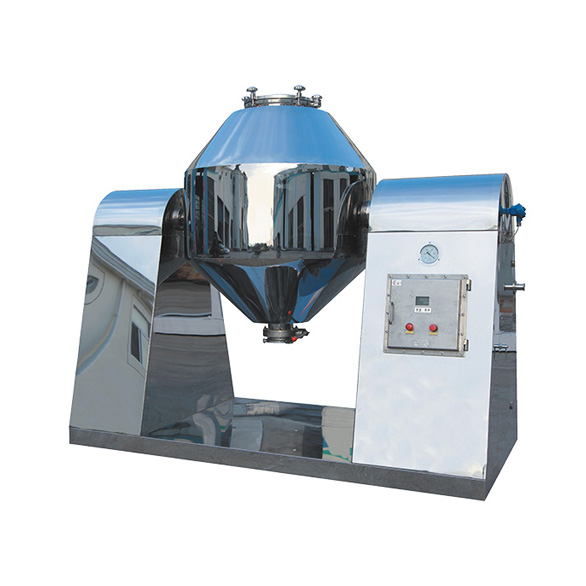

ZLG Series Vibrating Fluid Bed Dryer

Product Details

Description:

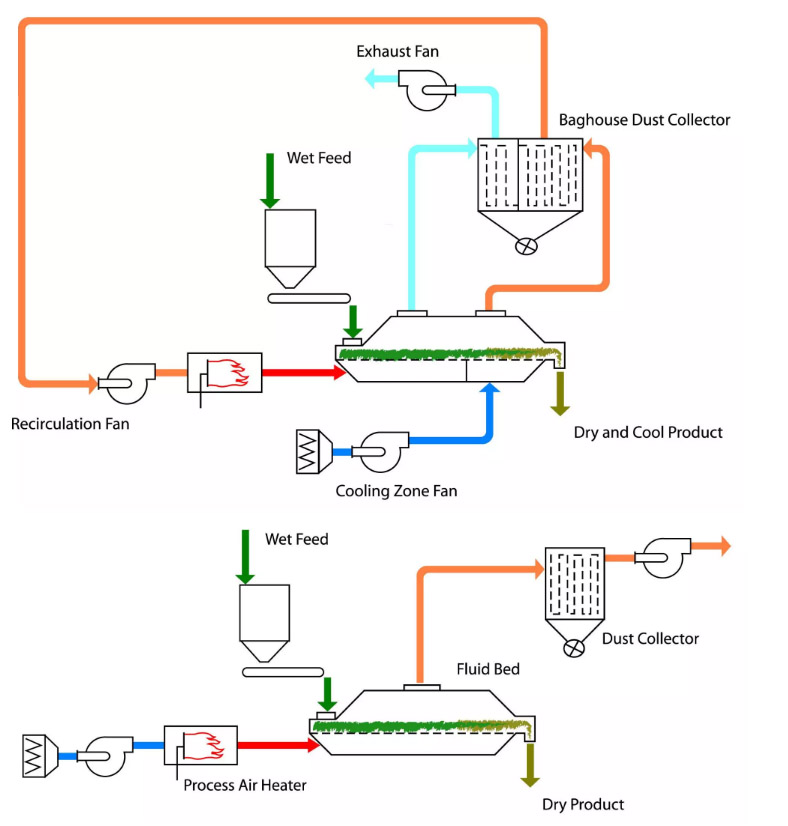

Principle

Raw material is feed into the machine from equipment inlet and move forward continuously along with the horizontal direction under vibratory power. The hot air passes through fluidized-bed and exchange with raw materials’damp, then the wet air is dusted by cyclone separator and exhausted from air outlet, the dried material is discharged through finished material outlet.

Scope of Application

Pharmacy and chemical industries: all kinds of granular tablet and granule, boric acid, borax, hydroxybenzene, malic acid, malay acid.

Foodstuff and construction industries: lees, monosodium glutamate, edible sugar, edible salt, mine residue, bean, seeds.

It can also be applied for raising material damp or cooling raw material.

Features

Raw material is heated uniformly, heat exchanging is sufficient, drying capacity is high.

Compared with ordinary drier, it can save energy up to 30%.

The vibration is driven by vibratory electric device, it has those benefits: stable operation, convenient maintenance, low noise and durable.

Fluidized state is stable, no dirty corner and broken out situation.

Easy regulation and wide suitability. Inside the machine, raw material’s thickness, moving speed and amplitude change can be adjusted.

Small damage to raw material’s surface, this equipment can be applied for drying easy broken materials; raw material’s anomaly shape can not affect drying effect, operation environment is clean.

Raw material and air cross pollution are effectually prevented by using fully sealed structure. Drying environment is very sanitary.

TECHNICAL PARAMETERS

| Model |

Area of fluidized- bed(m2) |

Temperature of air inlet (°C) | Temperature of air outlet (°C) | Capacity to vappor | Vibration motor | |

| moisture (kg/h) | Model | Power (Kw) | ||||

| ZLG3×0.30 | 0.9 | 70-140 | 40-70 | 20~35 | YED10-6 | 0.75x2 |

| ZLG4.5×0.30 | 1.35 | 70-140 | 40-70 | 35~50 | YED10-6 | 0.75x2 |

| ZLG4.5×0.45 | 2.025 | 70-140 | 40-70 | 50~70 | YED16-6 | 1.1x2 |

| ZLG4.5×0.60 | 2.7 | 70-140 | 40-70 | 70~90 | YED16-6 | 1.1x2 |

| ZLG6×0.45 | 2.7 | 70-140 | 40-70 | 80~100 | YED20-6 | 1.5x2 |

| ZLG6×0.60 | 3.6 | 70-140 | 40-70 | 100~130 | YED20-6 | 1.5x2 |

| ZLG6×0.75 | 4.5 | 70-140 | 40-70 | 120~140 | YED20-6 | 1.5x2 |

| ZLG6×0.9 | 5.4 | 70-140 | 40-70 | 140~170 | YED20-6 | 1.5x2 |

| ZLG7.5×0.60 | 4.5 | 70-140 | 40-70 | 130~150 | YED30-6 | 2.2x2 |

| ZLG7.5×0.75 | 5.625 | 70-140 | 40-70 | 150~180 | YED30-6 | 2.2x2 |

| ZLG7.5×0.90 | 6.75 | 70-140 | 40-70 | 160~210 | YED30-6 | 2.2x2 |

| ZLG7.5×1.2 | 9 | 70-140 | 40-70 | 200~260 | YED40-6 |

3.0x2 |

| A | B | C | D | E | F | Weight (kg) | |

| ZLG3×0.30 | 3000 | 300 | 1000 | 900 | 450 | 1700 | 1250 |

| ZLG4.5×0.30 | 4500 | 300 | 1000 | 900 | 450 | 1700 | 1560 |

| ZLG4.5×0.45 | 4500 | 450 | 1150 | 900 | 525 | 1800 | 1670 |

| ZLG4.5×0.60 | 4500 | 600 | 1300 | 900 | 600 | 1850 | 1910 |

| ZLG6×0.45 | 6000 | 450 | 1150 | 900 | 525 | 1800 | 2100 |

| ZLG6×0.60 | 6000 | 600 | 1300 | 900 | 600 | 1850 | 2410 |

| ZLG6×0.75 | 6000 | 750 | 1450 | 900 | 675 | 1900 | 2340 |

| ZLG6×0.9 | 6000 | 900 | 1600 | 900 | 750 | 2000 | 3160 |

| ZLG7.5×0.60 | 7500 | 600 | 1500 | 1000 | 600 | 1950 | 3200 |

| ZLG7.5×0.75 | 7500 | 750 | 1650 | 1000 | 675 | 2050 | 3600 |

| ZLG7.5×0.90 | 7500 | 900 | 1800 | 1000 | 750 | 2150 | 4140 |

| ZLG7.5×1.2 | 7500 | 1200 | 2100 | 1200 | 900 | 2500 | 5190 |

Wechat

Wechat